1.Maximum 12 weighing/sorting stages.

2.Excellent processing and weighing speed by FPGA hardware filter with intelligent algorithms.

3.Automatic parameter setting by intelligent product sampling.

4.Ultra-fast dynamic weight tracking and automatic compensation technology to effectively improve the weighing stability.

Weight Sorting Grading Machine Multi-sorting Checkweigher

(0

reviews)

Estimate Shipping Time:

3 Days

Sold by:

Inhouse product

Inhouse product

Price:

$9,000.00

/Pc

Refund:

Share:

Top Selling Products

-

G2000 Women Belted Dress

$53.90

Product Overview

Fanchi-tech Dynamic Checkweigher Systems

FA-MCW series Multi-sorting Checkweigher has been widely applied in fish and shrimp and a variety of fresh seafood, poultry meat processing, automotive hydraulic attachments classification, the daily necessities weight sorting packing industries, etc. With a Fanchi-tech multi-sorting checkweigher customized to your specifications, you can depend on accurate weight control, maximized efficiency, and consistent product throughput, even in rugged industrial environments.

FEATURES AT A GLANCE

5.Easy operation by friendly touch screen HMI.

6.Storage of 100 product programs.

7.High capacity operation statistic record with USB data output.

8.High precision structural components and stainless steel 304 frame by CNC tooling.

6.Storage of 100 product programs.

7.High capacity operation statistic record with USB data output.

8.High precision structural components and stainless steel 304 frame by CNC tooling.

Right elevation

Front elevation

Left elevation

Combination Systems--Compact and Reliable Inspection

Fanchi's Dynamic Checkweigher systems are available in combination with metal detectors or x-ray machine, or labeling machine, which can save footprints greatly. Our checkweighers rapidly weigh products in motion on a conveyor line and automatically reject off-weight products, as specified in the product setup.

PRODUCT SPECIFICATIONS

High-speed High Accuracy Dynamic Checkweigher Specifications

Model | FA-CW160 | FA-CW230 | FA-CW300 | FA-CW360 | FA-CW450 | ||||

Detecting Range | 3~200g | 5~1000g | 10~4000g | 10g~10kg | 10g-10kg | ||||

Scale Interval | 0.01g | 0.1g | 0.1g | 1g | 1g | ||||

Detecting Accuracy | ±0.1g | ±0.2g | ±0.3g | ±1g | ±1g | ||||

Detecting Speed | 250pcs/min | 200pcs/min | 150pcs/min | 120pcs/min | 80pcs/min | ||||

Weigher Size(W*L mm) | 160x200 /250/300 | 230x250 /350/450 | 300x350 /450/550 | 360x450 /550/800 | 450x550 /700/800 | ||||

Material of Construction | Stainless Steel 304 | ||||||||

Belt Type | PU Anti Static | ||||||||

Line Height Options | 700,750,800,850,900,950mm +/- 50mm(can be customized) | ||||||||

Operation Screen | 7-inch LCD Touch Screen | ||||||||

Memory | 100 kinds | ||||||||

Weigh Sensor | HBM high accuracy load cell | ||||||||

Data Retrival | USB Port(Standard); Ethernet/RS232(Optional) | ||||||||

Conformity | CE (Declaration of Conformityand Declaration of Manufacturer); UL(certified by our US customer) | ||||||||

Software Language | English(Spanish/French/Russian, etc optional) | ||||||||

Rejector | Flipper/Pusher/Flapper/Air Blasting/Drop-down,etc(Optional) | ||||||||

Inline Heavy Duty Dynamic Checkweigher Specifications

Model | FA-CW500 | FA-CW600 | FA-CW700 | ||

Detecting Range | 0.1~25kg | 0.1~50kg | 0.1~60kg | ||

Scale Interval | 1g | 1g | 1g | ||

Detecting Accuracy | ±5g | ±10g | ±15g | ||

Detecting Speed | 40pcs/min | 35pcs/min | 35pcs/min | ||

Weigher Size(W*L mm) | 500x600/800 | 600x1200 | 700x1200 | ||

Material of Construction | Stainless Steel 304 | ||||

Belt Type | PU Anti Static | ||||

Line Height Options | 600,650,700,750,800,850,900mm +/- 50mm(can be customized) | ||||

Operation Screen | 7-inch LCD Touch Screen | ||||

Memory | 100 kinds | ||||

Weigh Sensor | HBM high accuracy load cell | ||||

Rejector | Heavy Pusher Rejector | ||||

Air Supply | 5 to 8 Bar (10mm Outside Dia) 72-116 PSI | ||||

Operating Temperatures | 0-40℃ | ||||

Self-diagnosis | Zero error, photosensor error, setting error, products too close error. | ||||

Other Standard Accessories | Windshield cover(colorless and clear), photo sensor; | ||||

Power Supply | AC110/220V, 1phase, 50/60Hz, 750W | ||||

Data Retrieval | Via USB(standard), Ethernet is optional | ||||

Key Components

● German HBM high speed load cell

● Japanese Oriental motor

● Danish Danfoss frequency converter

● Japanese Omron Optic sensors

● Japanese Oriental motor

● Danish Danfoss frequency converter

● Japanese Omron Optic sensors

● French Schneider Electric Unit

● US Gates synchronous belt

● Japanese SMC pneumatic unit

● Weinview industrial touch screen

● US Gates synchronous belt

● Japanese SMC pneumatic unit

● Weinview industrial touch screen

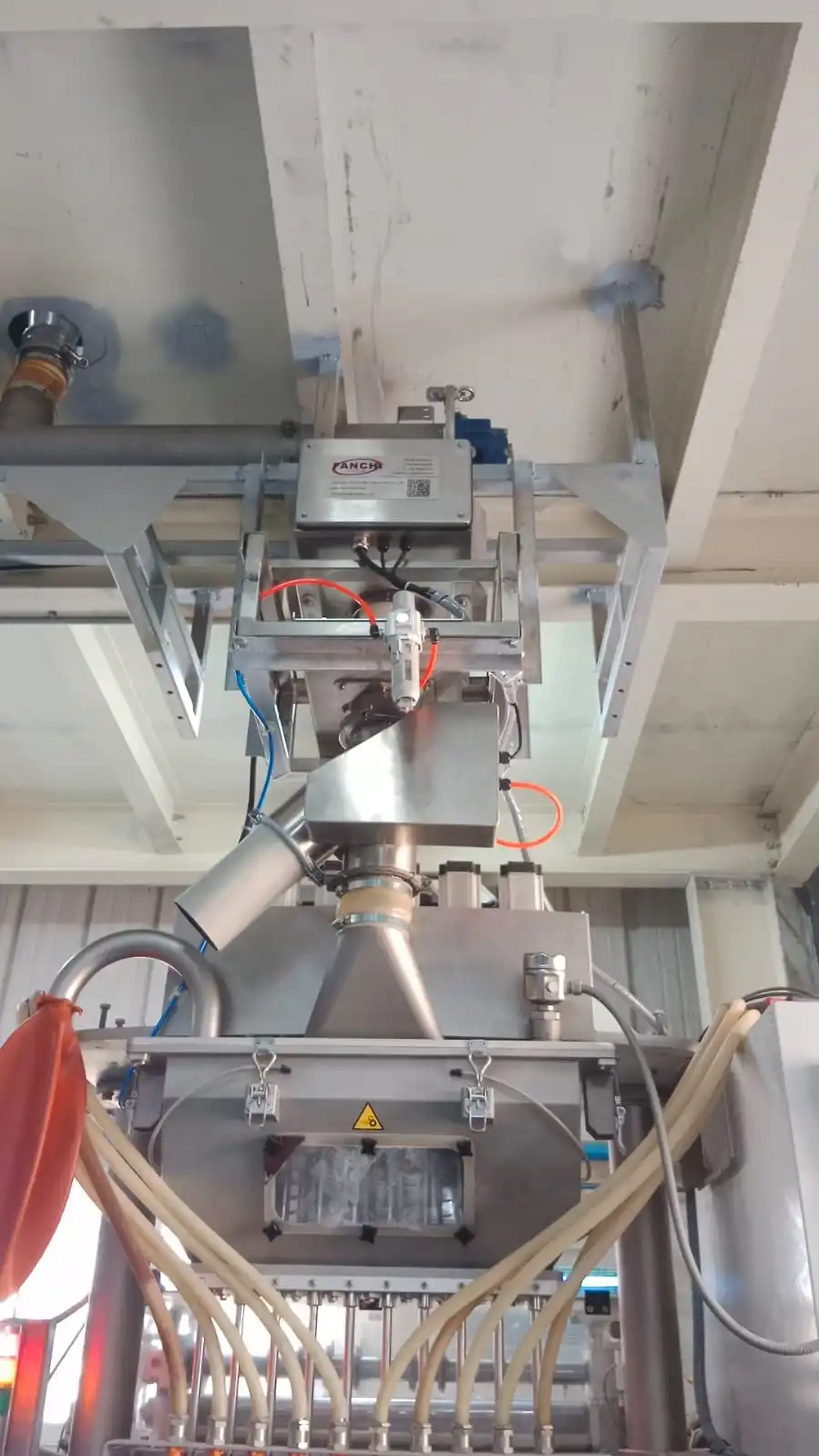

Successful Project

Company Profile

Company Profile

We’re a group company owning Fanchi and ZhuWei brands, founded in 2013, and now being an industry leader in the custom fabrication, finishing of sheet metal products and product inspection equipment. In Sheet Metal Fabrication Industry, our ISO-certified company handles everything from pre-production prototypes to high-volume production runs, while performing all fabrication and finishing in-house. This means we can provide high-quality, quick-turn parts at competitive prices. Our versatility means that, for example, we can design, fabricate, finish, silk screen, assemble and ship custom sheet metal enclosures and assemblies. We assure quality at every step of the process with computerized and in-process inspections, and regular troubleshooting. Working with OEM’s, assemblers, marketers, installers and servicers, we offer the “full package” of product development and fabrication, from start to finish. The typical products/projects we’ve made are including Electronic Equipment, Bill payment kiosks, Check sorters, Filter Enclosures, Electrical Control Cabinets, etc.

In Product Inspection Industry, we’ve been designing, manufacturing and supporting inspection equipment used to identify contaminants and product defects within the food, packaging and pharmaceutical industries, principally offering Metal Detectors, Checkweighers and X-Ray Inspection systems, believing that through superior product design and engineering the production of higher quality equipment with customer-satisfied service could be achieved.

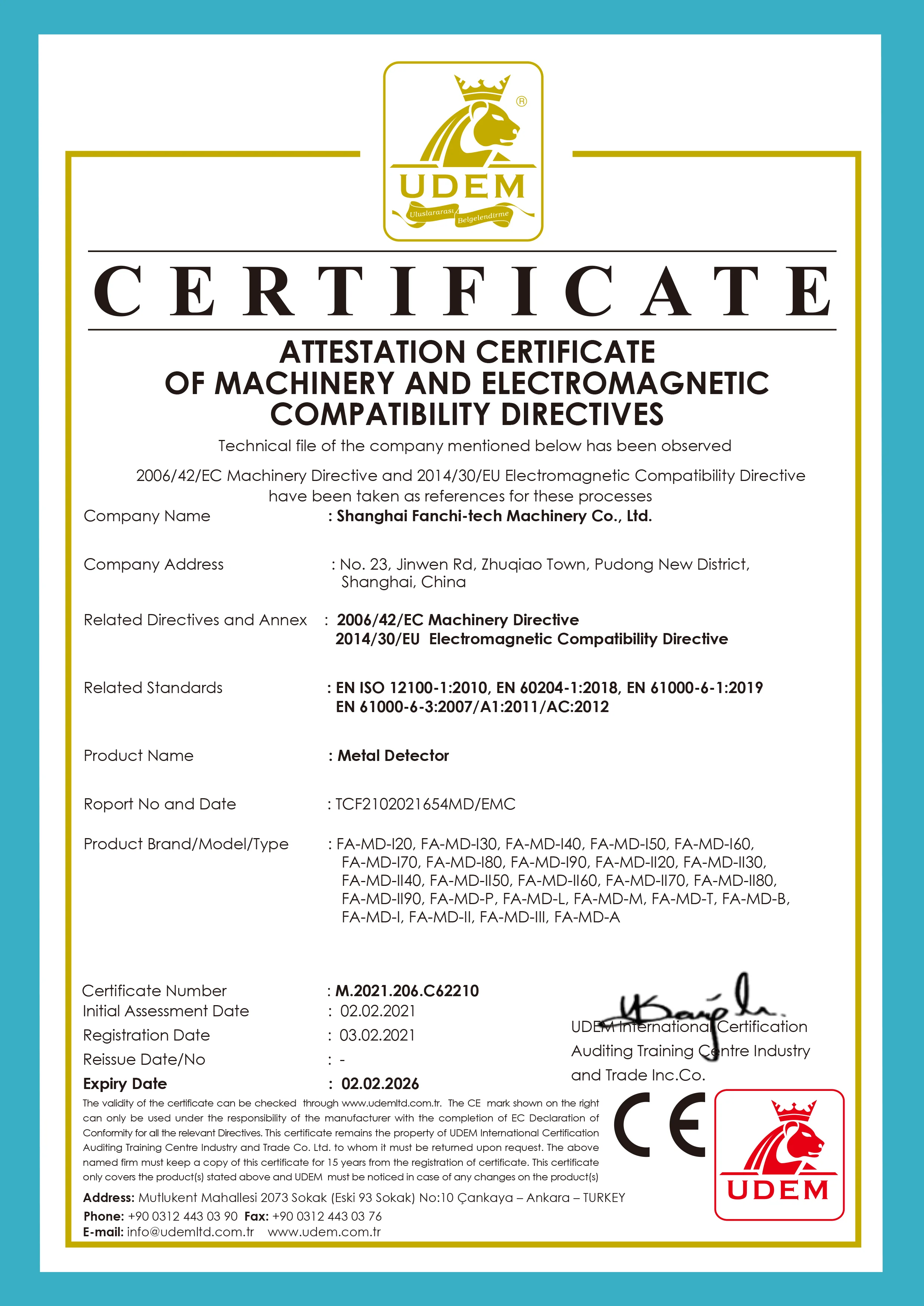

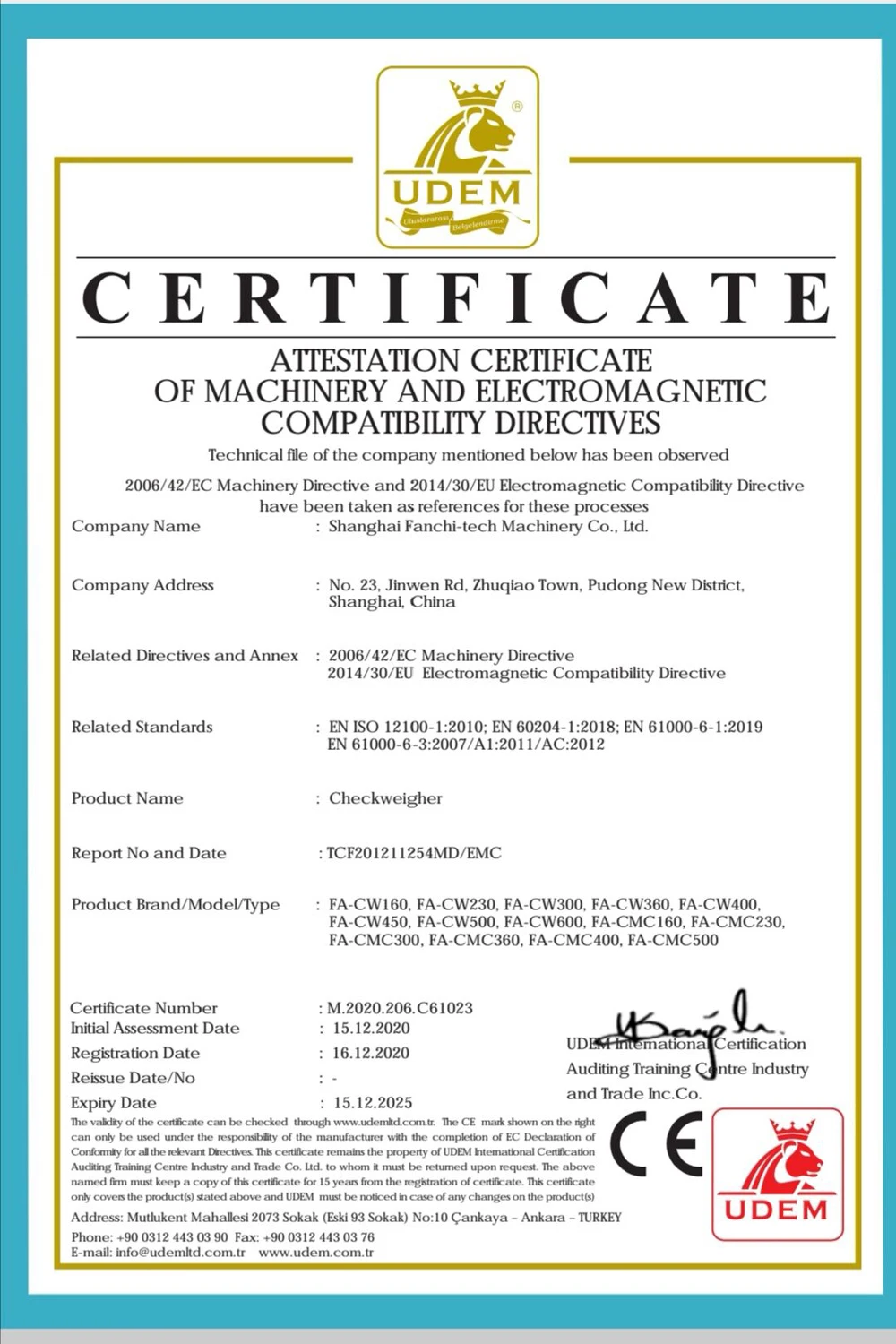

Our quality and certification: our Quality Management System is at the heart of everything we do and combined with our measurement standards and procedures, it meets and exceeds the requirements of ISO 9001-2015. Besides, all our products are fully compliant with EU safety standards with CE Certificate, and our FA-CW series Checkweigher is even approved by U L in North-America(through our distributor in US).

With integration of our Sheet Metal Fabrication Business, our Product Inspection sector has the following advantages: short lead times, modular design and excellent availability of spare parts, coupled with our passion for customer service, allows our customers to: 1. Comply with, and exceed, product safety standards, weight legislation and retailer codes of practice, 2. Maximize production uptime 3. Be self-sufficient 4. Lower lifetime costs.

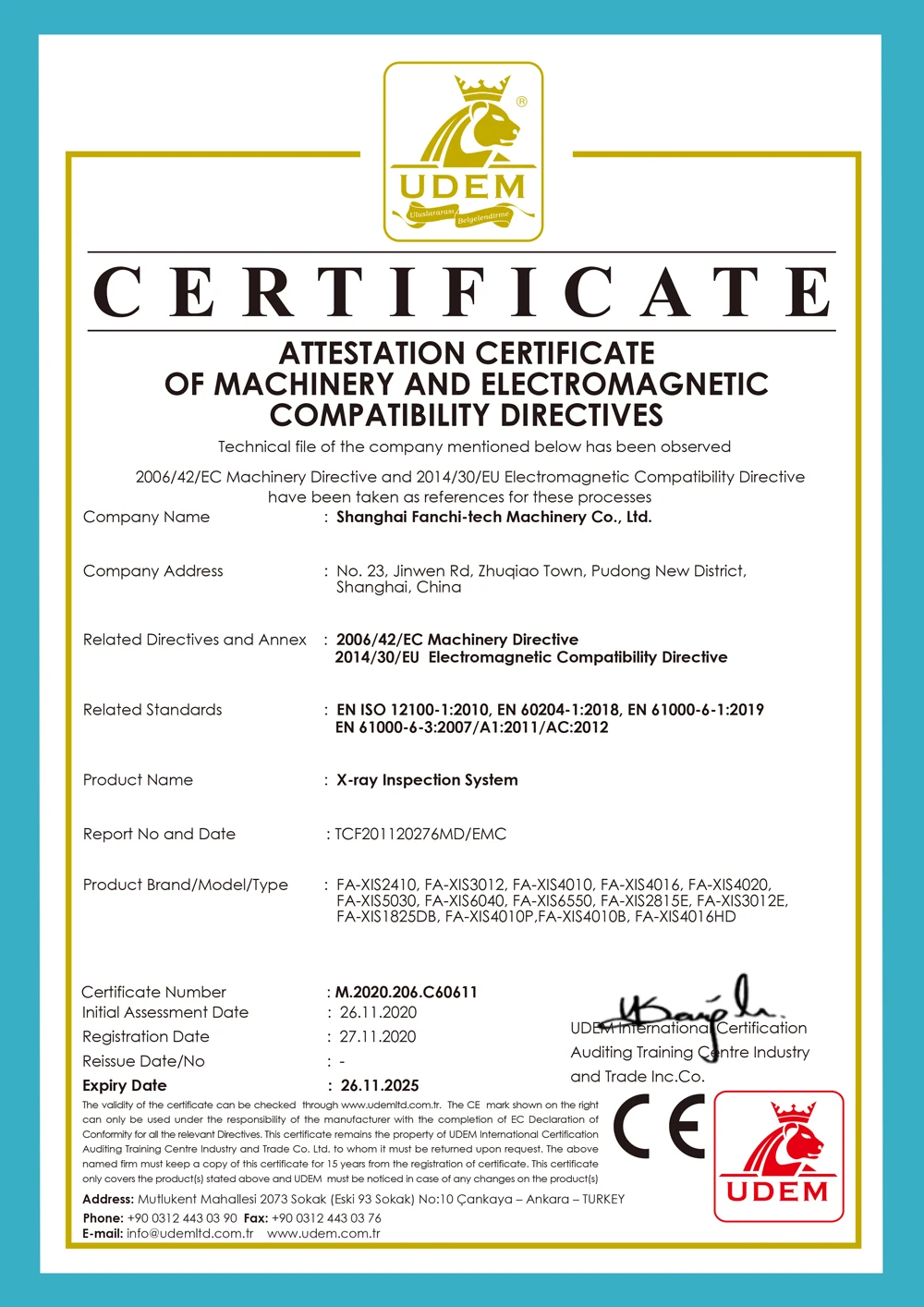

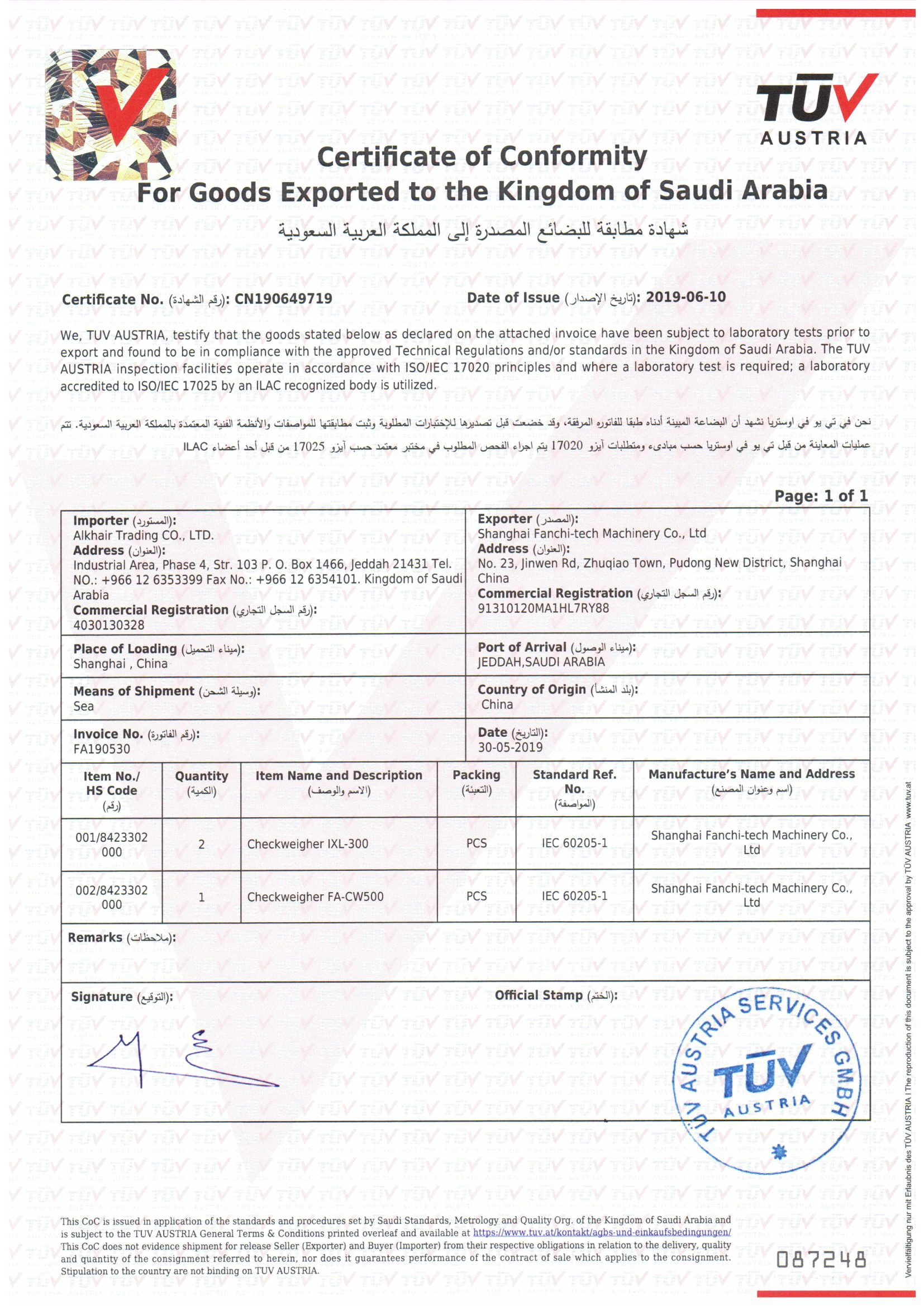

Certifications

Fanchi CE for Metal Detector

Fanchi CE for Checkweigher

Fanchi CE for X-ray Machine

UL Certificate Achieved by our Agent

Fanchi Group ISO Certificate

SASO Certicate

After-sale Services

After-sale services

Fanchi-tech recognises that providing great service, with great people on time, every time shows you the value of their investment in

our company. Our cost effective designs and industrial ruggedness has ensured a longevity of high standard world-wide equipment.

For reliability, serviceability we make our machines with standard and universal parts so once you own a machine in emergency's

you are able to get your local fitter or local electrician to look after them. 12 months parts and labor is warranted on all

equipment installed and supplied by Fanchi

our company. Our cost effective designs and industrial ruggedness has ensured a longevity of high standard world-wide equipment.

For reliability, serviceability we make our machines with standard and universal parts so once you own a machine in emergency's

you are able to get your local fitter or local electrician to look after them. 12 months parts and labor is warranted on all

equipment installed and supplied by Fanchi

FAQ

1. What is a Checkweigher?

A checkweigher is an automatic machine that checks the weight of packaged goods while in motion and rejects any products that are over or under the set weight requirement.

2. Why is a Checkweigher Important?

Having a reliable checkweigher is a crucial component of your quality control program. A Checkweigher can help your business comply with government regulations and ensure product consistency and flow.

The key functions and benefits of a checkweigher include:

* 100% product checking.

* Prevents potential product recall by rejecting under-filled containers.

* Saves on lost revenue by reporting and optionally rejecting overfilled containers, with a potential payback in a matter of

months.

* Helps optimize the overall production process and avoid productivity time-loss.

* Ensures customer satisfaction.

Checkweighers assure that every product leaving the factory is within your specification, helping you save money and maintain your brand reputation and quality.

The key functions and benefits of a checkweigher include:

* 100% product checking.

* Prevents potential product recall by rejecting under-filled containers.

* Saves on lost revenue by reporting and optionally rejecting overfilled containers, with a potential payback in a matter of

months.

* Helps optimize the overall production process and avoid productivity time-loss.

* Ensures customer satisfaction.

Checkweighers assure that every product leaving the factory is within your specification, helping you save money and maintain your brand reputation and quality.

3. What industries use checkweighers?

Checkweighers are prevalent in the food, cosmetics and other consumer goods production facilities, since almost all these products are packaged and sold by weight. But any industry that measures the quality of its product or product components by weight, can also benefit from a checkweigher, including industries such as pharmaceuticals and technology. A checkweigher can also inspect contents by quantity (pills and screws, for example) because of the close relationship between quantity and weight.

4. What causes product weight variations?

Many obstacles and setbacks can cause product weight variations, including: '

* Change in product density.

* Humidity and temperature changes.

* Human error or negligent personnel.

* Product build-up around the nozzle.

It’s difficult to know what kind of problems or issues may occur on the production line, making it near impossible to ensure an exact fill every time. A checkweigher can help you rest easy, knowing any error will be detected and corrected before a product leaves your facility.

* Change in product density.

* Humidity and temperature changes.

* Human error or negligent personnel.

* Product build-up around the nozzle.

It’s difficult to know what kind of problems or issues may occur on the production line, making it near impossible to ensure an exact fill every time. A checkweigher can help you rest easy, knowing any error will be detected and corrected before a product leaves your facility.

There have been no reviews for this product yet.